Giotto

The Giotto wheels are designed for competition-level roller skating, and are the most popular Roll-Line© wheels.

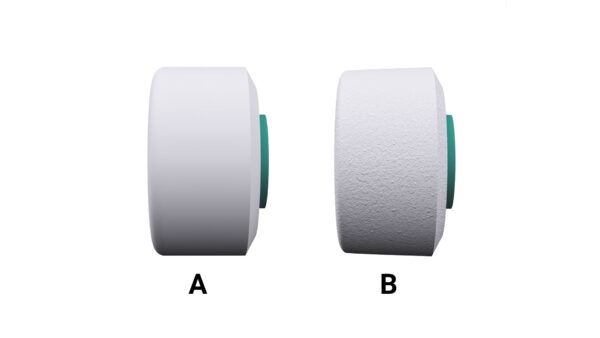

- Monocoque wheels produced via injection of a mix of thermoplastic polymer materials.

- Provide an optimal compromise between grip and roll, thanks to their tapered profile.

- The rounded finish allows for use in competitions with a minimal adjustment time.

- Brilliant and elegant chrome coverage.

- Available in five hardnesses (colors) and two diameters: 57mm and 55mm

- Available in sets of 8 wheels (It is at the discretion of each reseller to sell units in smaller quantities).

Roll-Line does not sell directly to the public; to complete your purchase, please refer to an official reseller.